Will 3D Printing Replace Traditional Manufacturing?

Southern California Company Complements Additive Manufacturing with Subtractive and Molding Processes

Dinsmore, Inc. has been featured in Design 2 Part magazine.

“Considered more of a novelty than a serious manufacturing process a dozen years ago, additive manufacturing — often called 3D printing — is gaining more momentum Connector Pinsevery day as a viable, versatile, precision process for a variety of prototyping and manufacturing needs. Since the first additive processes — SLS and SLA — hit the marketplace in the late 1980s, manufacturers have tried to fit the innovative processes into as many industry niches as possible. Additive manufacturing is now reaching a prominent place in a variety of markets, from the hobbyist and small -scale inventors to sophisticated design firms, small OEMs, and gigantic Fortune 500 companies that require critical, precision prototypes and small volume production runs.

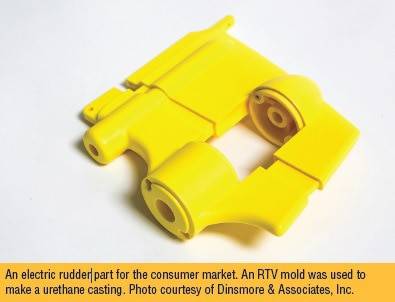

FRSLA (Fine Resolution SLA) is an advanced SLA process that Dinsmore developed and trademarked themselves. ‘We’ve worked to focus and refocus the beam of the lasers to Ruddercreate highly-detailed parts with FRSLA,'” said Ward. “It is ideally suited for industries like medical devices and aerospace, where small, precision parts are needed, and even for some consumer parts. We developed FRSLA over many years of working with resin manufacturers and printer manufacturers. We had customers that were requesting higher detail and finer resolution, and it just became an ongoing process of trial and error and discovery. We got to the point where we found what materials are best suited for this process.”