3D Printing in the Medical Field

What is it that keeps drawing more and more users to turn to 3D printing for medicine’s toughest questions? More than likely its printer’s variation, speed and cost are key factors in why the use of 3D Printers in the medical industry has been skyrocketing.

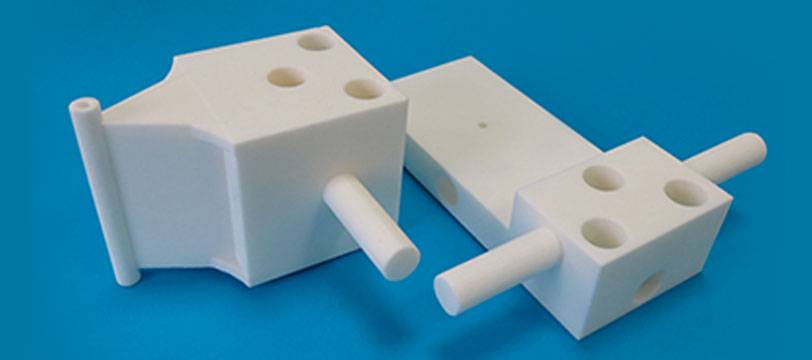

3D Printers can print using various materials, from glass to metal and everything in between. Plastic is the most common medium 3D Printer manufacturers use, but metal and glass are just starting to gain momentum. In August 2015, a company created the first FDA-approved, 3D printed pill, which could eventually allow the medicine to be personalized per individual.

Granted not all printers use different materials, but most 3D printers work with already installed 3D software. Once the product is designed, a 3D rendering can be easily and quickly printed. Allowing numerous prototypes to be developed and tested rather quickly.

Costs can still vary based on the complexity of a project, but since the materials have changed and the amount of steps in the development stage has shrunk, so has the cost. Granted products being developed in the medical industry are very likely one-time use, the overall cost is far less than a prototype developed using traditional methods.

3D Printing Manufacturers, like Dinsmore, Inc. are working closely with medical professionals to develop and fast track prototypes specifically designed according to their client’s needs. Allowing doctors and/or surgeons to approach each situation in a precise manner and give their patients a piece of mind knowing each surgery is specially tailored to his or her needs.