Exceptional Durability, Heat Resistance, and Strength

FDM (Fused Deposition Modeling) and FFF (Fused Filament Fabrication) are versatile 3D printing processes widely utilized across industries, from hobbyist projects to industrial applications. Both methods involve extruding a thermoplastic filament layer by layer onto a build platform, ensuring precise fabrication of complex designs.

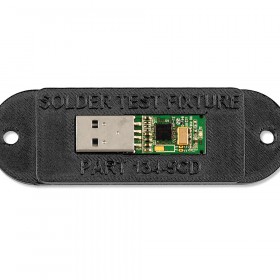

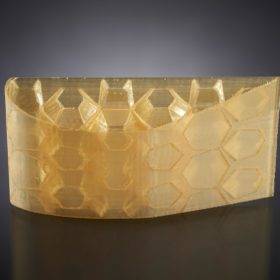

Using engineering-grade thermoplastics, FDM/FFF produces dimensionally stable parts with exceptional accuracy and a myriad of properties such as strength, thermal resistance, and durability. Our expert finishing services ensure that printed parts meet specific aesthetic requirements, enhancing their appeal and functionality.

Dinsmore Inc.’s FDM/FFF 3D printing services cater to diverse industries, from automotive manufacturing to consumer product development. Our expertise in these processes ensures that we meet the unique demands of each project, providing value and innovation every step of the way.